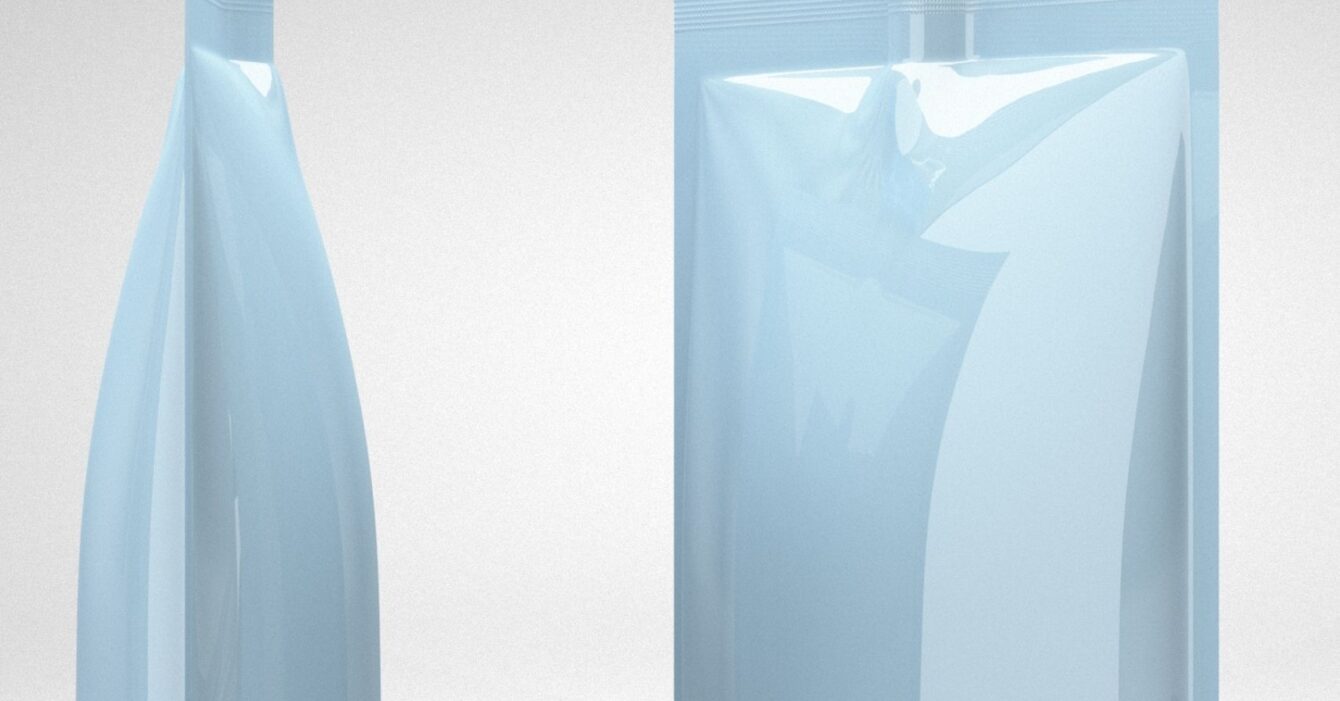

Flexible packaging is one of the fastest-growing segments in the packaging industry, and for good reason. It offers a unique combination of convenience, functionality, and sustainability that makes it a preferred choice for manufacturers and consumers alike. At Triopack, we specialize in producing high-performance, recyclable flexible packaging that meets the evolving needs of the global market.

Where Is Flexible Packaging Used?

Flexible packaging is widely used across multiple industries, including:

- Food & Beverage: Snack bags, coffee pouches, frozen food films, pet food packaging.

- Pharmaceuticals: Blister films, sachets, and medical product wraps.

- Agriculture & Chemicals: Fertilizer and pesticide pouches.

- Personal Care & Beauty: Sample sachets, single-use masks, and lotion tubes.

Its lightweight structure makes it ideal for high-volume products, while its adaptability allows for creative, brand-enhancing designs.

Benefits of Flexible Packaging

- Resource Efficiency: Uses less raw material compared to rigid packaging.

- Lower Transportation Costs: Due to its lightweight and space-saving properties.

- Extended Shelf Life: High barrier materials protect against moisture, oxygen, and UV light.

- Consumer Convenience: Resealable zippers, easy-open options, and portability.

Sustainable Solutions at Triopack

At Triopack, sustainability is a core value. Our flexible packaging products are available in recyclable mono-materials such as PE, PP, and PET, with barrier enhancements like EVOH for product protection. We also offer biodegradable and compostable films tailored to client requirements. By adopting solvent-free lamination and reduced-ink printing technologies, we ensure minimal environmental impact throughout the production cycle.

Choose Triopack for flexible packaging that delivers performance, sustainability, and brand distinction.